In the world of CNC machining, the ability to fabricate custom parts with precision is a valuable skill. The team at Tormach worked on a project, during a YouTube live streaming event, using Tormach’s 8L lathe and 1100MX mill to create custom bolts for an assembly. Here is the step-by-step process on how to craft these unique bolts with the 8L lathe and 1100MX mill.

Step 1: Lathe work with the Tormach 8L

We begin the process by setting up the 8L lathe. The goal is to create the threaded feature on the custom bolts. To start, use hex stock, ensuring it is securely held in a 5C collet. The hex stock provided a robust starting point for our custom bolts, offering both strength and aesthetics.

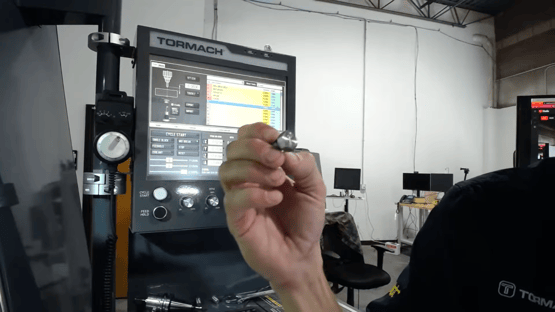

With the hex stock in place, I utilized the lathe to turn the stock and cut the threads for the bolts. The precision of the Tormach 8L allowed me to create threads that would perfectly match the intended application. After the threads were formed, I part off the bolt from the bar of stock, ensuring that each piece was of the desired length.

Step 2: Milling with the Tormach 1100MX

The next phase of the project involves transferring the bolts to the 1100MX mill. We will create a pocket face on each bolt, and this mill was the ideal tool for the job. To ensure consistency and accuracy, the bolts were secured to a Saunders Machine Works fixture plate. The fixture plate held the bolts firmly in place, guaranteeing that each one received the same precise treatment.

With the bolts securely held in position, we used the Tormach 1100MX to create the pocket face. The mill allowed for meticulous control over the depth and dimensions of the pocket. This step was crucial to the overall functionality and aesthetics of the custom bolts.

Step 3: Adding Custom Lettering

One of the unique aspects of this project is the need for custom lettering on the bolt heads. To achieve this, conversational programming in PathPilot®, Tormach’s CNC control software, was utilized. The conversational programming feature made it easy to input the text, font, and size specifications for the custom lettering. This level of control ensures that the lettering is precisely engraved on each bolt, meeting the project's specific requirements.

Conclusion:

The combination of the 8L lathe and 1100MX mill allows us to successfully craft custom bolts for the assembly. The precision and versatility of the machines is essential in achieving the desired results. From turning hex stock into threaded bolts, milling pocket faces, and adding custom lettering, this CNC machine setup provided the accuracy and control needed for this unique project.

This project underscores the importance of using the right tools for the job and the value of CNC machining in creating custom, high-quality parts. Whether you're a seasoned machinist or just starting out, Tormach’s CNC technology offers endless possibilities for turning ideas into reality.