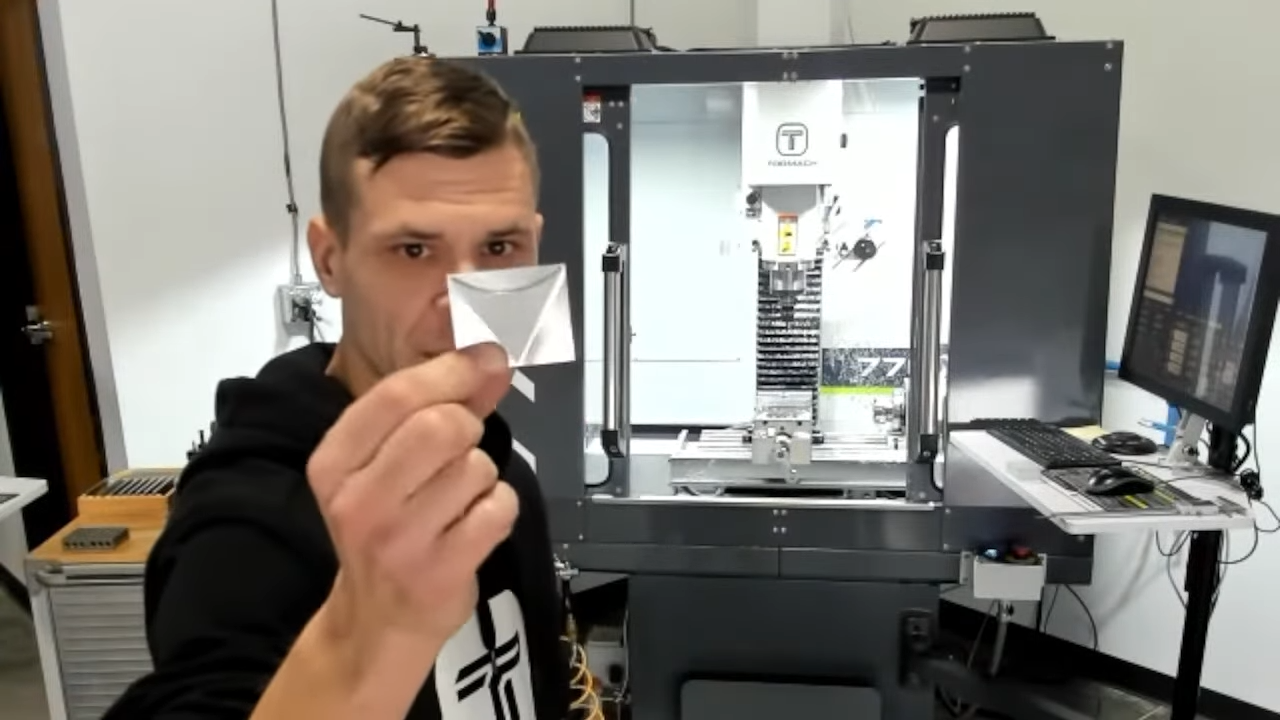

In a YouTube live session, a member of the Tormach team dove into the intricacies of cutting soft jaws on our 770MX CNC mill. This project is specifically for a triangular-shaped part with a significant radius. We were excited to tackle this challenge, considering the complexities that arise when attempting to machine such unconventional parts.

When dealing with a part that cannot be easily held with conventional methods like V-jaws or flat surfaces, a thoughtful approach is needed. Our setup involved a slot geometry within the CAD software, strategically designed to clear the points of the triangular part when placed in the pocket of the soft jaws.

Setting up soft jaw cutting on the 770MX CNC MILL

Our soft jaw setup enabled a two-operation process (op one and op two) while maintaining the same setup, showcasing its flexibility for handling multiple parts simultaneously if necessary. The soft jaws, featuring well-placed slots, provided a secure grip on the unconventional part without compromising its critical features.

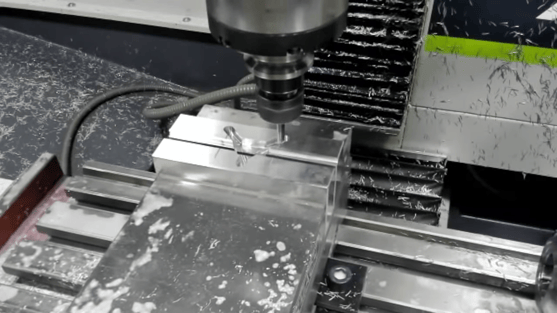

During the machining demonstration on the 770MX CNC mill, we manually faced the part, emphasizing the significance of having parallels between the jaws for accurate positioning. You must make sure you have a strong hold on the part to prevent interference with the soft jaws.

The setup highlighted in the video can be adapted for a secondary operation, which demonstrates the versatility of the soft jaw approach. Additional steps can also be taken to improve the process, such as adjusting speeds and feeds for enhanced efficiency.

Setting up soft jaw project for 770MX CNC mill in CAD / CAM

Transitioning to the CAD environment later in the project, we explain the geometry used for creating the soft jaws and machining the part. The process of generating slot geometry in Fusion 360 to overcome the challenges posed by the triangular part's corners is highlighted. Additionally, we touched upon considerations for toolpath compensation and showcased how different CAM software might handle sharp corners.

We hope this hands-on demonstration, coupled with explanations of CAD and CAM strategies, can help you when taking part in machining and soft jaw applications. Be sure to subscribe to our YouTube channel so you won’t any of our videos or YouTube Live sessions.