Last week we talked about using fixture plates for quick and repeatable setups, and asked blog readers to send us pictures of their fixture plate set ups as part of a contest. The winner of last week's blog contest is Fred Francouer from Université de Sherbrooke in Quebec, Canada. Fred's designed a clever setup that allows him to quickly attach several vises, a 4th Axis, work holding chuck, and even the Duality Lathe to his PCNC 1100. Thanks for sharing, Fred - you're the winner of a custom Tormach Shop Shirt. What we really like about this fixture plate system is how the individual components are designed to stack and install on each other. Check these out:

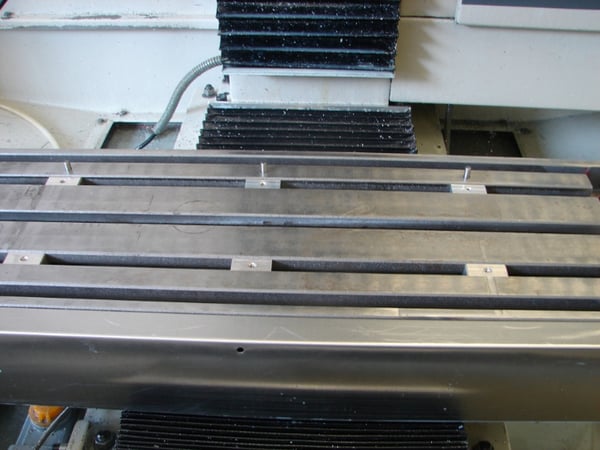

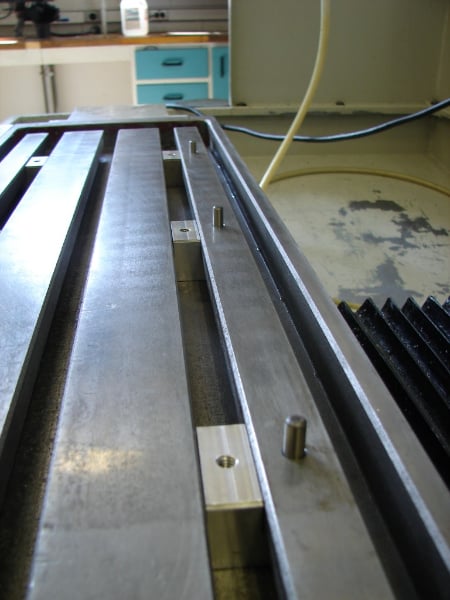

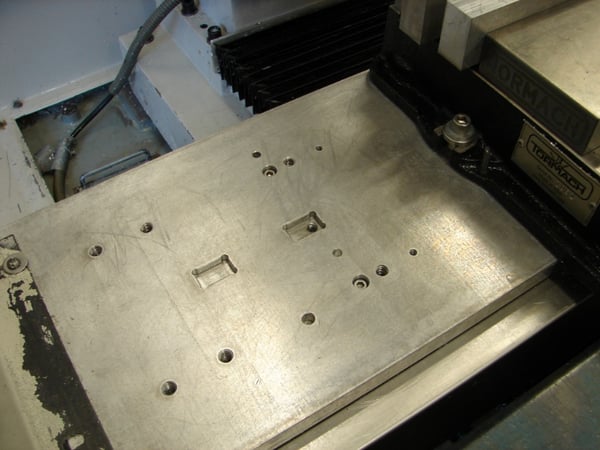

- First, several dowel pins have been installed on the table along with custom T-nuts. The pins let Fred quickly install his Duality Lathe when needed without having to align the lathe each time in X or Y.

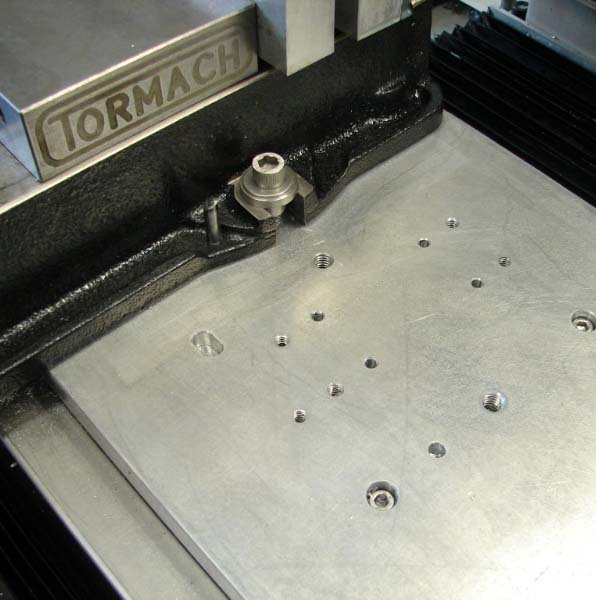

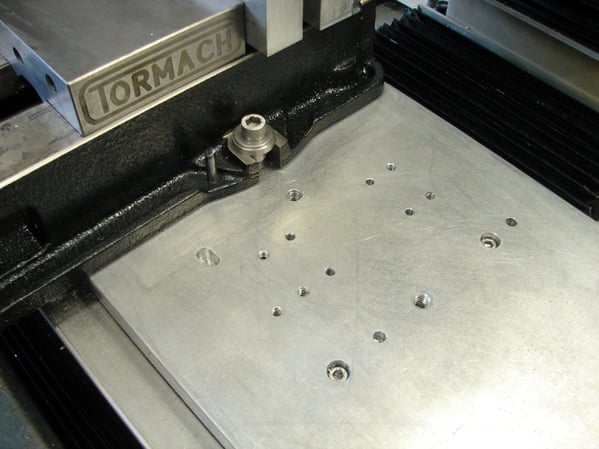

- A second fixture plate is design to accept the dowel pins on the table. Additional pins on this plate are used to locate the vise.

- On this same plate, slots have been milled to accept the 4th axis Table.

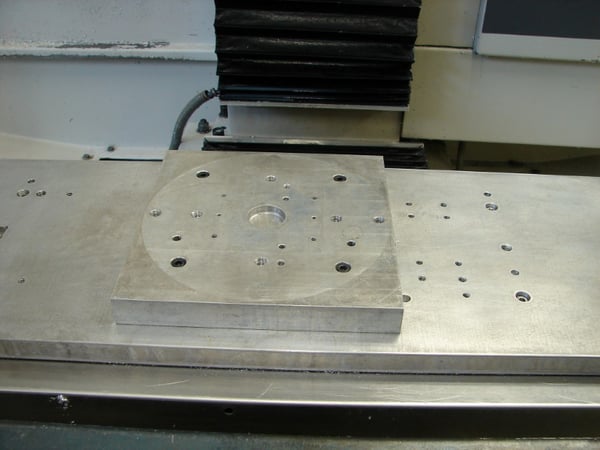

- With the vise removed, another smaller fixture plate can be mounted that accepts a 3 Jaw chuck for holding round bar stock vertically.

- The same plate also takes another smaller fixture plate as well.

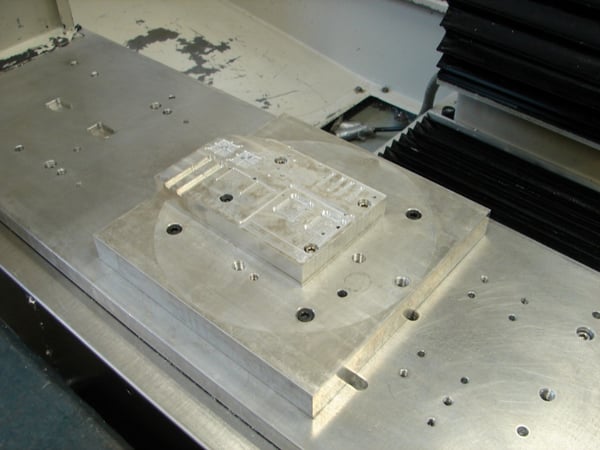

- And finally, here are 2 smaller tool maker vises on separate tool plates sitting on top of the large fixture plate. These are used to support the ends of long stock.