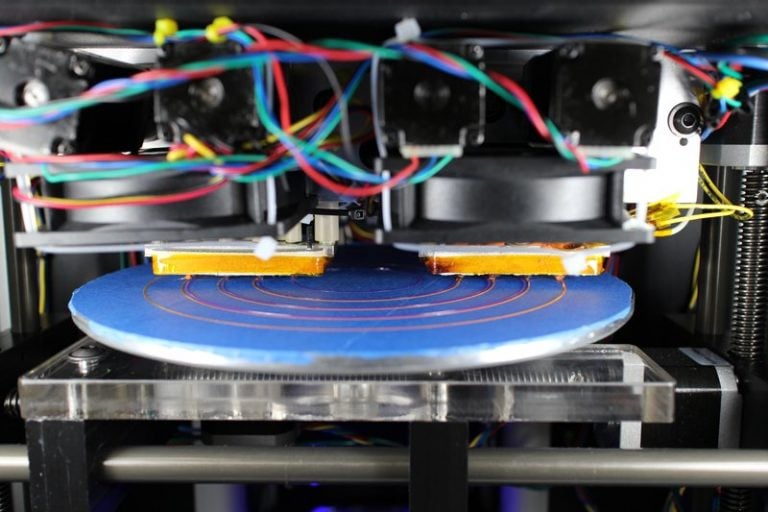

Founded by Nathan Patterson, Kevin Harris, and Nathan Schumacher, Radiant Fabrication in Fitchburg, Wisconsin hopes to bring 3D printing into the mainstream. Their consumer-level 3D printer, Lionhead™, incorporates 3D printing and 3D scanning into a single device. Using a voxel-based editing environment in their 3D modeling software, Radiant Li™ runs in an environment similar to the popular video game Minecraft.

With the scanner, printer, and software bundled, Radiant believes they have created one of the most durable and easy to use 3D printers available today. Current marketing efforts for the Lionhead are focused on public sector markets including schools and libraries. Patterson notes that the combined hardware and software package is a perfect fit for these environments.

“A lot of high schools, middle schools, and libraries are looking at purchasing a 3D printer for their location or district. We’ve got not only the hardware they need, but also the software that young people already know how to use.”

Radiant Fabrication purchased a Tormach PCNC 1100 for the purposes of product design and development as well as small-scale production.

“We’re using the PCNC 1100 to make components for the Lionhead, including all of the components for our polar-type mechanism. We also use the 1100 for facing various components created on a laser cutter and a router.

“The Tormach PCNC 1100 has been extremely helpful in developing the extruder drives and heater blocks. It has allowed us to create multiple versions of our print heads and filament drives and iterate on the designs very quickly. These components need to be repeatable and machined accurately,” Patterson added. “Filament drives tend to be the point of failure for a lot of 3D printers. The fact that we have been able to quickly make and test so many iterations has allowed us to converge to a great design."

He continued, “A lot of other printers have extruders that have been designed to be quickly taken apart for maintenance. This sounds great, but in reality, they’re designed that way because they fail so often.

“The Lionhead is different,” explains Patterson. “With other machines, filament drives can be so sensitive that holding the filament back with two fingers can stop it from working. Because we’ve been able to quickly iterate on our designs and also precision machine these parts, we’ve been able to create drives that are capable of exerting substantial forces on the filament without losing motor steps or stripping the material.”

For more information on the Lionhead 3D printer and the innovations at Radiant Fabrication, visit them online at www.radiantfabrication.com.