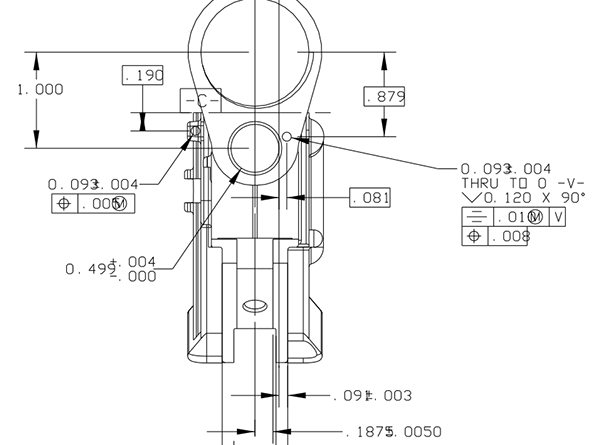

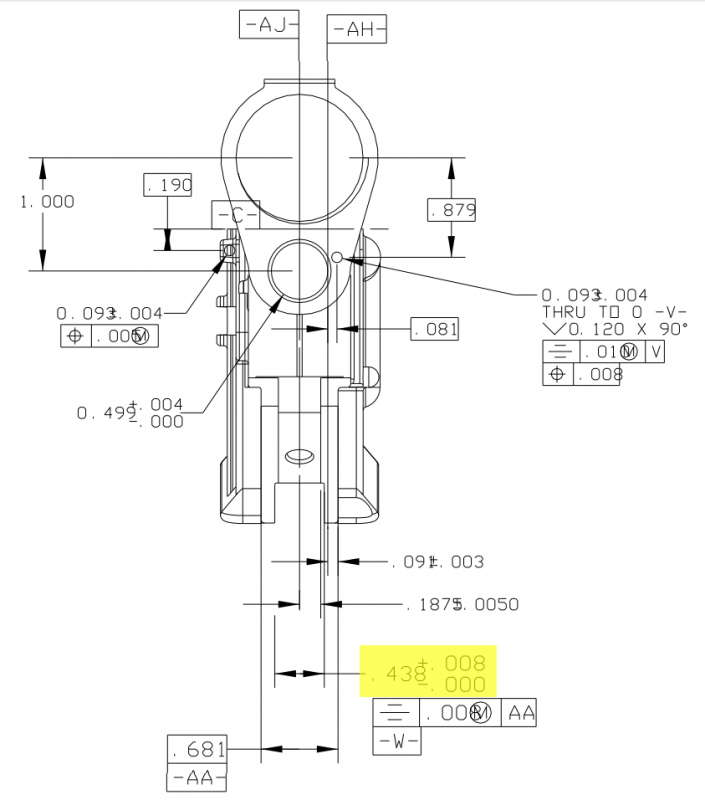

You probably already know this, but tolerances are important. If your product is a standalone part with only one component, tolerances may not be as important. Many machined parts, however, are destined to interface with another - whether part of a larger assembly or designed to be used with another product (such as an aftermarket car part). Tolerances are the key to making sure every part and piece of the assembly meshes together the way you intended. Tolerances separate good parts from great parts - so let’s take a look at a few types of fit. There are three important tolerance dimensions to be aware of. As an example, let’s take a look at the snippet of a drawing below, focusing on the highlighted dimension of .438” +.008” -0.000”:

•Basic Size (.438”) - the nominal or given dimension.

•Lower Deviation (-0.000”) - the difference between your Basic Size and the smallest allowed dimension (notice our part has no lower deviation, the smallest allowable dimension is .438”)

•Upper Deviation (+.008”) - the difference between your Basic Size and the largest allowed dimension (in our part, this is .008” meaning the largest allowable dimension is .446”).

When dealing with these tolerances, always think about what will be easiest to machine. In this example, trying to machine the feature spot on at .438” would cause more headaches than shooting for, say, .442”. Why is this? If your goal is to hit .438” every time, going even a little under that dimension means the part is out of tolerance and has to be scrapped. On the other hand, shooting for .442” cuts your allowable tolerance in half. Now you have wiggle room to miss your mark by .004” on either side of your goal and still be within tolerance.

Clearance Fit

In a clearance fit (sometimes known as a slip fit) the hole is larger than the shaft, pin, or part meant to mate with it. Clearance fits are used when the shaft needs to rotate or slide in the hole, and does not retain the shaft.

Location or Transition Fit

A location fit involves the hole being either the same size as the shaft or only nominally smaller. This is a semi-permanent way to retain a shaft commonly known as a press fit, and some amount of force is required to seat the shaft.

Interference Fit

An interference fit is a more permanent way to retain a pin or part. An interference fit requires either large amounts of force to press fit the shaft or heat (which we’ll talk about in the next section). In this type of fit, the hole actually has a smaller diameter than the pin intended to go into it. Although this amount of interference varies by material and application, often an interference fit as small as .001” (.025mm) is sufficient.

Considering Temperature in your Tolerances

When designing the Concorde jet, engineers had to account for the high temperatures caused by flying at supersonic speeds. This increase in temperature caused the entire plane to expand by 7 inches in the air compared to its length on the ground! Why is this? As you probably know, materials expand when heated. When working with parts that will be exposed to drastic changes in temperature, it is important to consider the amount the stock will expand or contract to maintain the desired fit. Each material has its own expansion coefficient, which, when used in combination with the change in temperature and part dimension will give you the amount of expansion or contraction.

Expansion is not only a factor in determining tolerance ranges, but you can use it to your advantage when retaining a pin or shaft. In much the same way that heat shrink tooling works, applying heat to a bore or hole will cause the diameter to increase. This allows a shaft that ordinarily would not fit to slip into the bore and become permanently retained when the part cools and shrinks. Unless the material is heated to that degree again during normal use, this creates a permanent way to retain hardware.

Specifying Tolerances

If you aren’t the one making some of your parts, specifying tolerances on a drawing is crucial. If another employee or shop manufactures the part, they could have seen only that specific part. Because they don’t have the full assembly and don’t always know the design intent, they can’t predict the necessary tolerance range and will apply a general tolerance (a common general tolerance for job shop work is +/- .005”). It’s important to know the general tolerance range of the shop and to clearly specify the tolerance on your drawing if a tighter tolerance is necessary.

Another factor to keep in mind is cost - as a general rule of thumb tighter tolerances are more expensive. There’s no reason to chase tenths on a purely aesthetic feature, and specifying unnecessarily tight tolerance will quickly drive up the cost of your part. Try to keep the tolerance range reasonable for the feature in question, and don’t specify unnecessary features.