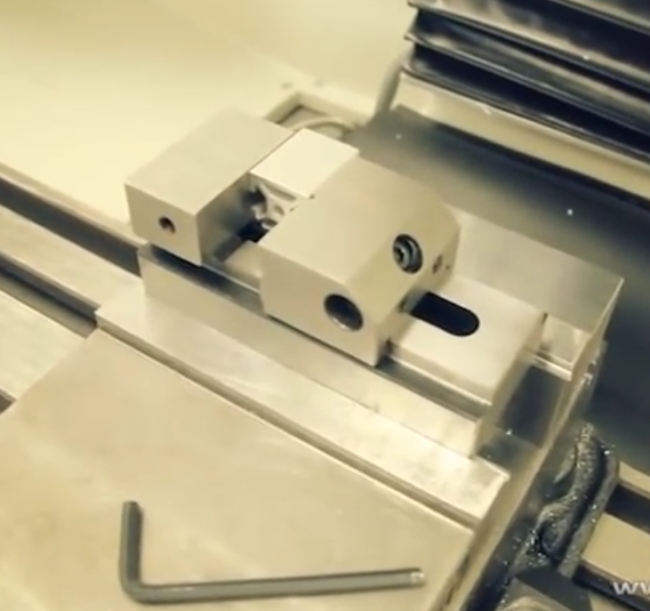

If you haven't seen toolmaker vises before, then it might not be immediately clear why you might need one. It turns out, however, that they are a very handy device to have in your work holding arsenal. Small tool maker vises are designed to be held inside a larger machinist's vise. Bigger Toolmaker vises can also be held directly to mill table via strap clamps or a magnetic chuck. Tool maker vises are excellent for holding delicate workpieces and also great for doing work on the end of a workpiece. Since the sides of the vise are precision ground, they can be easily used to do parallel or perpendicular work on opposing or adjacent sides of a workpiece without the need to re-indicate anything. Here's a quick video we put together with some ideas about how you might use a tool maker vise with a Tormach PCNC or other milling machine.

Other tool maker vise applications include:

- Working on the end of a pin or cylinder

- Flycutting and/or facing of small cross sections

- End Drilling

- Cross drilling

- Edge milling thin sections

We now have a whole family of tool maker vises available. Make sure to check them out here:

More Tormach Fab Lab Videos:

- 4th axis Basics - Using a 3 Jaw Chuck

- Fixture Plate Basics

- Getting Started with Tension/Compression Tapping

- Getting Started with Auto-Reversing Tapping

- How to Swing Indicate a Square

- How to Swing Indicate a Circle

- How to Bore an OD

- How to Bore an ID

- How to Use a Sine Vise

- Tips for using Strap Clamps

- How to Square a Block