Tormach CNCs have been called both versatile and robust - two things that don’t often coincide with each other. Even more so, the PCNC 1100 has often been called a gateway to CNC, as the machines are of a prosumer standard, yet they are simple and intuitive to operate. Andy Smith, who is graduate student in the Engineering Robotics Lab in the Mechanical Engineering Department at the University of Nevada-Reno, attests to the capabilities as he operates a PCNC 1100 in the lab.

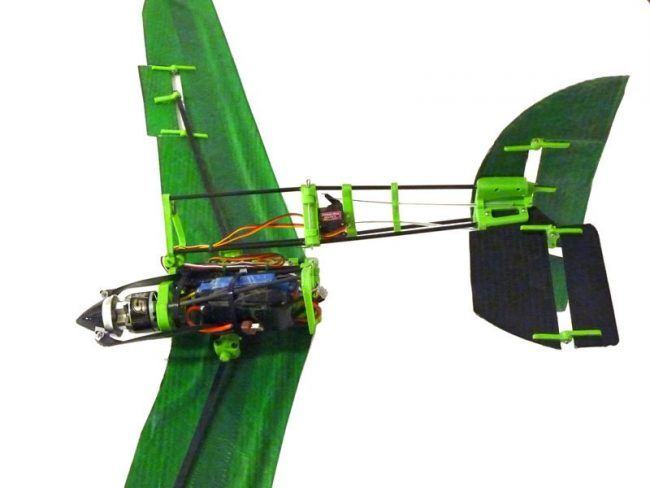

"I am overseeing the development of two autonomous unmanned aerial vehicles (UAVs), which are aerially deployed out of a rocket and then carry out their mission. One is a fixed wing craft and the second is a quadrotor," Andy explains. In the lab, he uses the Tormach for creating molds for composite work, primarily.

“Using the Tormach CNC we are able to easily to create complex wing shapes to develop wings that would otherwise be beyond our capabilities to make,” Andy explains. "We also use the Tormach CNC to create some metal parts for mounting hardware." Andy didn’t have any experience with CNC machines before the Tormach.

“Prior to using the Tormach CNC I used a manually operated mill,” he says. “It was good for some projects, but it is almost impossible to create complex three-dimensional curving surfaces by hand, which the Tormach does reliably. The 1100 allows us to create components that would otherwise be impossible to create.”

As a graduate student, Andy works with undergrads in the Engineering Robotics Lab. As students came into the lab, most had no experience with a CNC mill, and with his own greenhorn experience, he found that there is an intimidation factor when it comes to CNC.

"Most students have very little machining experience and are easily intimidated when moving from the manual mill to the CNC,” he explains. “Fortunately, once they fabricate their first component on the Tormach, they see how simple and powerful the machine is."

Andy found the Tormach to be “incredibly easy to use and intuitive.” With new, inexperienced students always coming in, he finds that the ease of use of the 1100 works well in a learning environment.

“In a matter of minutes with g-code and a piece of raw material I can have the Tormach CNC producing my components. The setup is very straightforward and the Tormach CNC runs with minimal interaction once it begins.”

The Tormach PCNC 1100 has improved the university’s manufacturing capabilities and helps make students’ transition from manual mills to CNCs easier. “The Tormach allows us to take on more complicated research projects,” Andy says.

Whether he’s finishing UAVs for graduate projects or helping students who are new to CNC become acclimated with the machine, Andy has found a growing list of uses for the University of Nevada-Reno’s PCNC 1100.