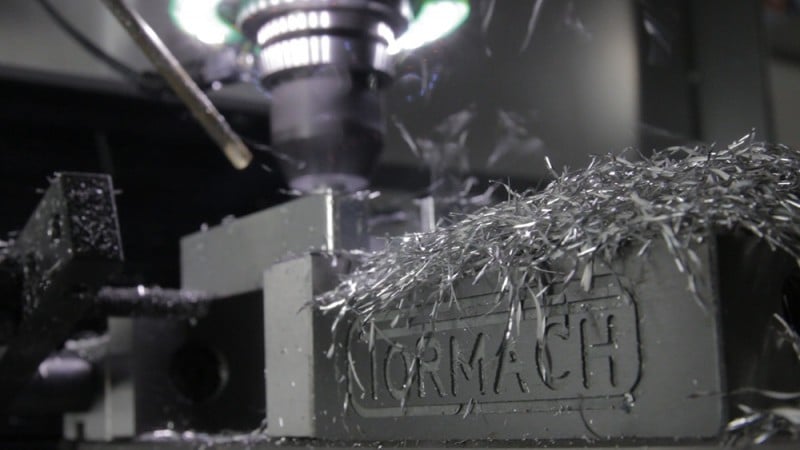

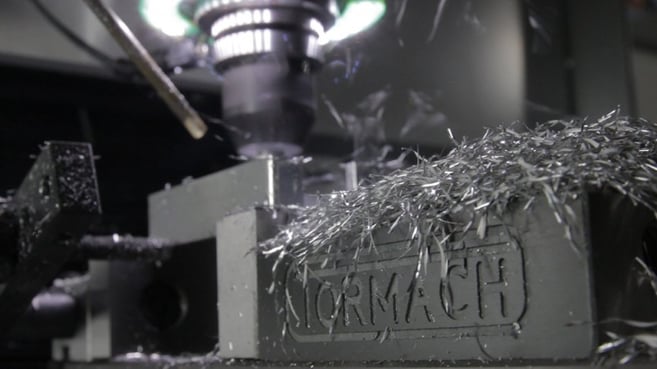

Last week, pre-orders started on our newest mill, the PCP 440. As a company, Tormach has always made strides to enable the ideas of our customers, and this new machine lowers the bar for entry into making real parts from real materials. With a footprint measuring 42” x 36” (W x D), the PCNC 440 fits into almost any workspace. A stout cast iron frame provides the rigidity necessary for metal cutting that smaller gantry 3D carving machines just don’t have. The R8 spindle design is a slightly shorter version of the spindle in our PCNC 770, with a speed range of 300-10,000 RPM. The spindle is driven by a ¾ HP brushless DC motor using a 2-stage pulley and belt design that provides with both high speeds for finishing and enough torque at lower speeds to cut steel and hard materials. Just like our bigger PCNC mills, the PCNC 440 is designed for economical accurate motion control. Each PCNC 440 has dovetail ways and with tapered gibs. Sliding surfaces are coated with a low friction PTFE-filled Acetyl bonded sliding surfaces, similar to Turcite®. Each axis is driven by ballscrews with anti-backlash double ball nuts and has maximum speeds of 135 IPM (X,Y) and 110 IPM (Z). Also like our other mills, this machine is controlled by PathPilot, which provides an approachable interface for both beginners and veteran machinists. With PathPilot, the PCNC 440 can run industry-standard G-code or utilize the software’s conversational programming. Our hope is that the PCNC 440 can provide the first opportunity for beginners to step into the world of real CNC machining. But don’t overlook that it is also a very effective CNC mill for prototyping or secondary operations tool for the experienced machinist.