The Rundown on Runout

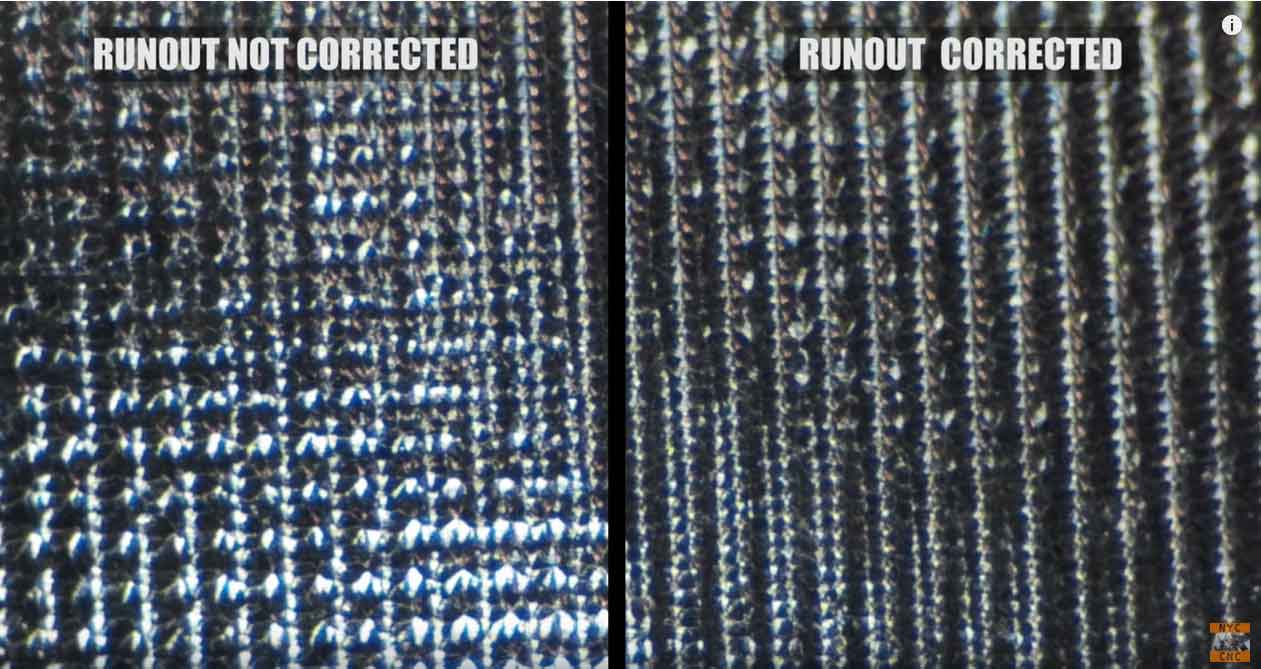

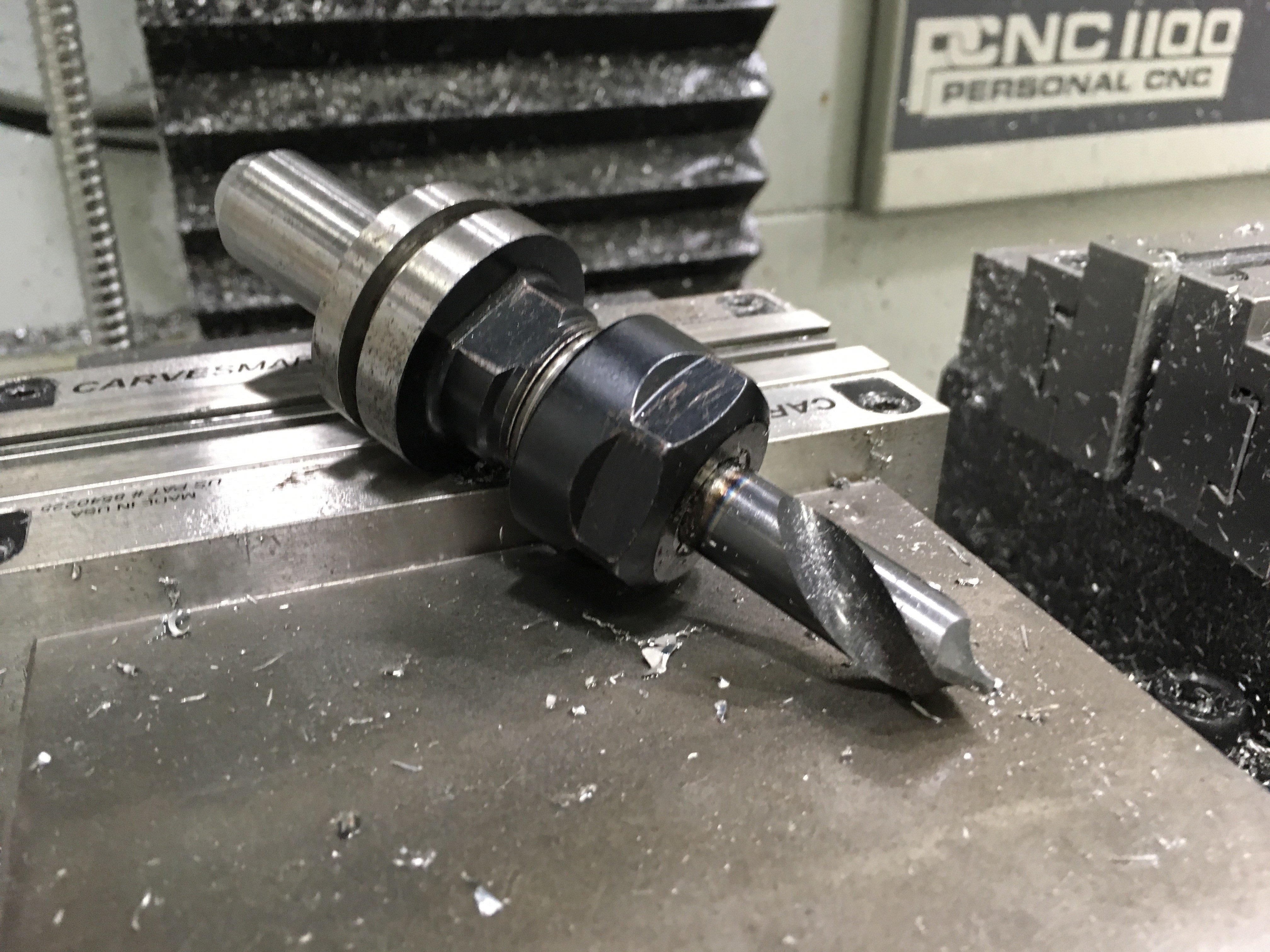

As covered in our 10 Things No One Tells You About Machining article, runout is everywhere! However with most tools we use this amount is negligible. Using, say, a 3/8” endmill with .0008” of TIR won’t have significant consequences (especially when roughing). Unless you’re chasing tenths, the runout is such a small percentage of the tool’s overall diameter (~0.21%) that it wont have any noticeable affects. As you small diameter tools, this percentage begins to increase. Using a 1/32” endmill with the same runout amounts to a TIR that is 2.56% (about a 10x increase!). This can result in uneven wear, chatter, bad surface finish, missing tolerances, and even broken tools.