Don Breneman purchased a PCNC 1100 as an affordable secondary operation CNC mill to solve a costly bottleneck in his machine shop. A standing order for oil and gas components was keeping his Haas VF2 busy around the clock, but each part required a serial number. The engraving operation for parts of varying sizes accounted for more than half of the cycle time on the single machine. “Using an 8000 lb. machine for engraving is like killing a fly with a hammer,” he explains. By offloading the engraving operation, Breneman felt he could free up time on the VF2 for higher-value jobs.

Initially, Don had purchased a bench top mill to use for secondary operations, like engraving, but had problems with machine quality, repeatability, and precision, which left him searching for a more robust option. When he purchased his Tormach PCNC 1100, he immediately saw an increase in production.

“When I first set up the Tormach I had a huge workload, so the first engraving setup was simply a hinged bar which clamped down to hold the parts,” he explains. “I used a standard subroutine for the engraving G-code and used G52 offsets on the X-axis to repeat for the number of parts that were clamped.” That system immediately doubled his production, as it operated while he tended to the Haas machine.

Don continues, “Even though I had doubled my output, I was still faced with a couple problems. I do five series of parts, which vary in overall dimension but are otherwise similar rectangular shapes.” This required moving his clamp setup for each batch run. “The biggest hurdle, though, was part flatness – I only engrave about .007” deep. Any warping (from variable clamping pressure) in the parts meant that the engraving was either too deep or too shallow.”

He began to investigate ways to automate the fixturing to improve engraving quality and further reduce cycle time. Don spoke with a local company about an automation cell for his process.

“They showed me a cell with a small robotic arm that could do the process. When I asked the guy for a ballpark figure on that system, his response was, ‘around $300k.’” Undaunted, Don turned to Zbot, a Tormach Authorized Reseller and Solution Provider in Austin, TX, to assist with creating a low-cost automation process built around his PCNC 1100 using the Tormach M-code I/O interface kit (PN 32616) to control the fixturing and part loading mechanisms via the part program.

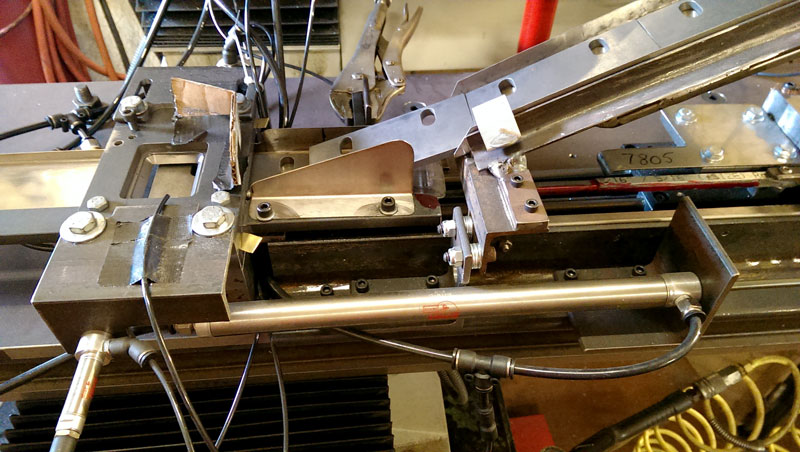

“I built the basic clamping fixture, found some used pneumatic cylinders on eBay, and bought Tormach’s IO board. At first, I hand-loaded the part and hit the cycle start button. It would activate the clamp and call the engraving subroutine. When it finished, the system would release the clamp and wait for me to swap parts.

That initial step didn't speed things up versus clamping several parts, but it did make the engraving uniform and eliminate part-to-part quality issues. After that I just kept visualizing the next step needed and automated it, until I had the current system.”

Don has been utilizing both his Tormach and his Haas as a complete production facility for his customer. He explains how valuable the PCNC 1100 has become to his shop, saying, “Like 3D printers, the intermediate-sized equipment opens up a new world to people who want to experiment with their ideas or set up production fixtures. I can envision a row of Tormach machines linked with part handlers, all I need is more hours in the day.”

Now, Don commits his PCNC 1100 to all engraving operations. Combined with his customized automation system, this machine provides a perfect solution in Don’s shop as a secondary operations machine, helping him make more parts faster.