Daniel Hienzsch is the resident engineer at Supplyframe’s design lab in Pasadena, CA, where they use their PCNC 1100 for a broad array of engineering endeavors.

“When Supplyframe was talking to me about taking over the design lab,” explains Hienzsch, “They kept talking about the different equipment that they had there, but they really kept talking about this thing called the Tormach.” When the lights came up in the lab, Hienzsch was introduced to the world of personal CNC.

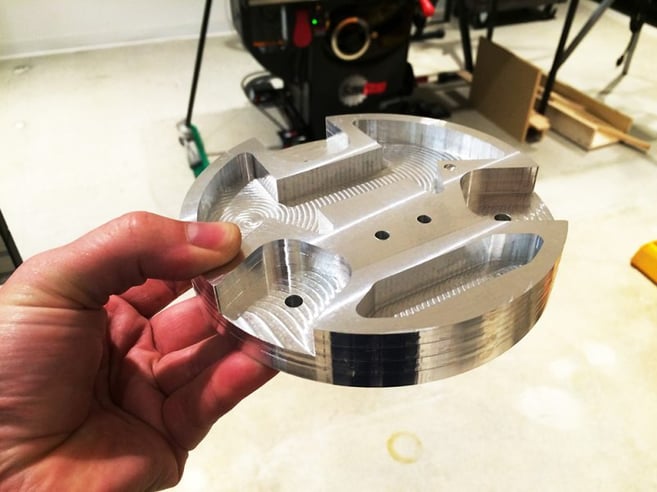

“The design lab exists for a number of purposes,” he continues. “The area where our Tormach really comes in is where we’re fostering engineering teams.” Supplyframe brings in and helps support different teams to develop various projects. “Part of those projects will always involve some kind of enclosure or housing or some structural element,” which lends to prototyping and even some light manufacturing on the PCNC 1100.

Supplyframe is connected to Hackaday.io, which is a community of developers, hackers, and all-around makers. “The design lab functions to take everything that we do in the virtual world, which is Hackaday and that much larger community, and give it a physical reality,” explains Hienzsch. “A place where we can actually take the ideas that these people are having and these engineers are developing and give them a place to grow. Consequently, for those teams that we invite into the design lab, we have all this fabrication equipment of which the Tormach is an essential part.”

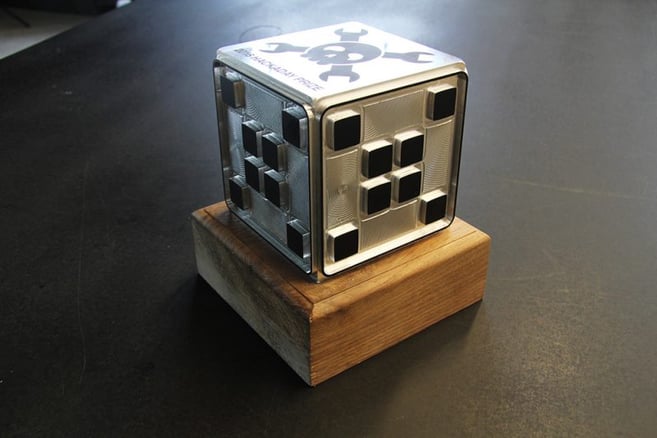

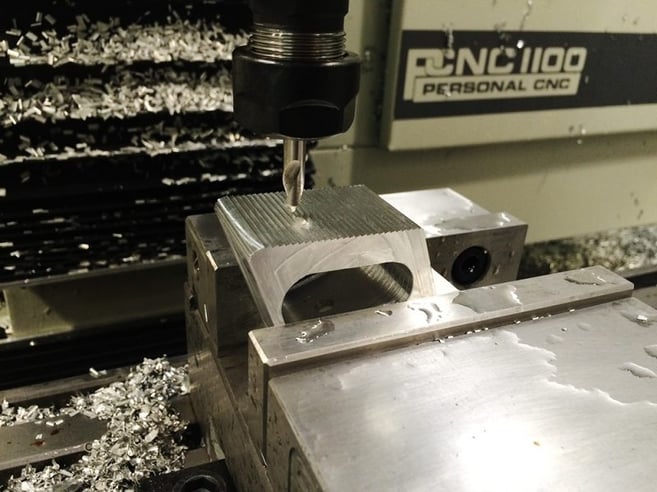

Supplyframe also sponsors a design and engineering challenge each year, and the winner gets $100k, as well as a residency at the design lab. “For that endeavor, I was asked to build the trophy. I wanted it to be a weighty trophy, so I thought a four-inch block of aluminum would be cool. I ended up recessing the trophy logo onto each of the faces.”

“I have the good fortune to make a lot of mistakes,” Hienzsch continues, “And as it turned out, the Tormach is very forgiving in that regard. I regularly crash the end mills, but apparently, I’m one of the few who has managed to break a TTS holder right at the spindle. You have to make mistakes to gain the experience. That’s great, because a lot of the engineers that we end up working with have these brilliant ideas, in terms of what they want to build, but don’t necessarily have that experience in fabrication or manufacturing.”

With a huge variance in projects, Supplyframe’s PCNC 1100 gets put through its paces. “I’ve gotta say the Tormach support, and I don’t want this to sound like I’m the sales pitch for Tormach,” he explains, “But the support… I talked with one of the techs for like an hour and a half to get an issue figured out. To me, that shows tenacity on the part of support. That’s very satisfying to me – to be able to talk with somebody that is willing to spend the time until the problem actually gets fixed.”

Supplyframe has seen a lot of success using their Tormach mill, but they’re excited to keep pushing the envelope and see what other projects it can help create.