It’s that time of year where we reflect on all the things we’re thankful for! While we’re all thankful for our families and good health, as machinists, what are we thankful for? This list isn’t exhaustive, as I’m sure we’ve missed a few things, but here are nine things the machinists at Tormach are thankful for.

9. CNC

This may seem a bit obvious, but let’s take a moment to reflect on what the world would be like with only manual machine tools. Manual tools still have their place, but the world of CNC has given us the ability to easily and more efficiently make things.

8. Silly Putty®

This kid’s toy/machinist’s tool is often overlooked as a valuable part of any workbench. You can use putty to check depths and finishes, or even as workholding in some circumstances. And that’s beside the fact that it makes for some quality amusement while waiting for a program to finish. Read: 9 Things You Didn't Know You Needed on Your CNC Workbench [youtube]ClDxPkNOKis[/youtube]

7. SmartCool™

Not only can this little accessory help direct coolant after a tool change, it can more efficiently clear away chips. That’s especially helpful when machining certain materials like aluminum and brass, whose chips tend to clog up your tooling. With the SmartCool™, you can use your tooling to its fullest potential.

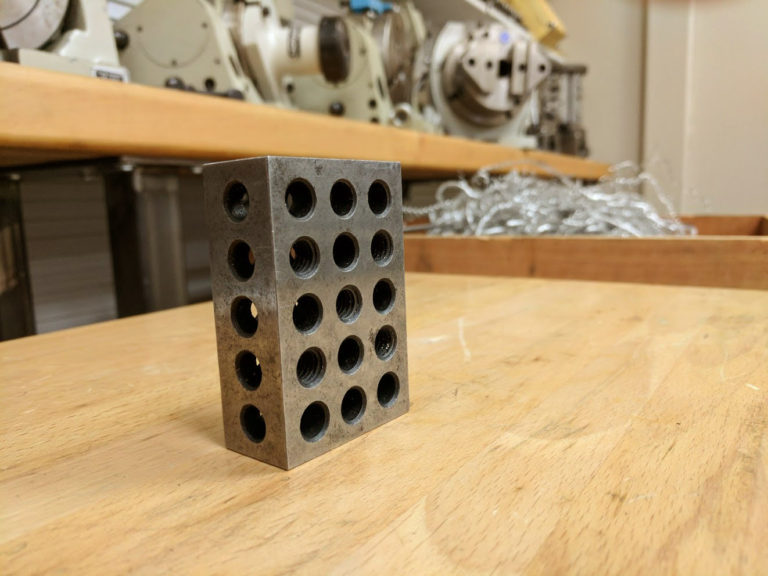

6. 1-2-3 Blocks

With these little blocks, you get a uniform surface that helps you take quick measurements, make better estimations, and adapt your offsets on the fly. What’s more, you can easily use 1-2-3 blocks to help with workholding and all sorts of customized tweaks in your setups. The best part is that they’re precision-ground yet inexpensive, making them both trustworthy and expendable.

5. Shear-Hog

Any machinist who does a lot of cutting in aluminum is extremely thankful for this tool, which is so named because it’s perfect for hogging through aluminum. Better yet, it leaves a great surface finish! Also, if you’re a fan of just watching chips fly – let’s be honest, we all get hypnotized by shredding chips – this tool is excellent at turning blocks of aluminum into chips. [youtube]CdJwGKhun8o[/youtube]

4. DIJET®

Like the Shear-Hog, this cutter makes piles of chips, but instead of cutting aluminum, the DIJET® High-Feed Mill shreds through steel. If you really want a fantastic show, this cutter makes all the chips you can handle.

3. Machinery’s Handbook

In this day and age, you can quickly find most information with a quick Google search, but our machinists at Tormach are still thankful for Machinery’s Handbook. For over 100 years, this comprehensive guide has provided lots of raw insight for machining and mechanical engineering. Even with a world of information at our fingertips, it’s still a vital piece of any tool set.

2. Adaptive Roughing

This machining strategy is incredibly useful, making roughing strategies faster and more efficient. Adaptive roughing provides faster stock removal and helps maintain a constant tool load, which leads to faster parts and longer tool life. So, it’s easy to see why we’re thankful for this little gem when programming parts.

1. Haimer

Almost every machinist who owns a 3D sensor by Haimer says they don’t know how they ever managed without one. Our team of machinists at Tormach are incredibly thankful for the sensor because it helps to quickly and precisely indicate edges, surfaces, or hole centers. Happy Thanksgiving!