Everyday there are more and more CNC entrepreneurs finding ways to build businesses using their machine tools. With machines like the Tormach lineup of mills, the barrier for entry into making your own products is lower than ever. There’s no need for a massive capital expense budget or access to a massive shop - you can start a CNC business out of your garage.

Joshua Ladlee is making knives with his business, Patient Zero Balisong. His love of knives and knife making came from growing up in a family of hunters, where a knife was a tool that you always had. “Knives and knife making is an art form, the variety of knife styles has always really intrigued and inspired me.”

His introduction to machining started in his youth as well. “My uncle used to work at a machine shop, I really looked up to him when I was younger. He'd always make really cool stuff, like one time he made a cannon that would fire crab apples as ammo. That kind of introduced me to metalworking, but it wasn't until recently I discovered I could build a machine shop in my garage without breaking the bank.”

That’s when Ladlee purchased a PCNC 440 with financing from Geneva Capital. “Geneva Capital been absolutely fantastic to work with, the process was insanely easy,” he explains.

Tormach PCNC 440 + TITANS of CNC = New Business

While Ladlee’s family introduced him to the machine shop world, he had no experience with actually using a machine. “[August 2020] was literally my first time ever touching any kind of machine, manual or CNC.”

He purchased a PCNC 440 to start prototyping parts for his knife making business, but the machines were out of stock at that time. While waiting for his backorder to ship, Ladlee took to learning everything he could from TITANS of CNC: Academy. “I wanted to be as prepared as possible for when the delivery truck came with my machine. I had the TITANS Building Blocks Kit, plenty of aluminum, and the Titan 1M programmed. I was just ready to get started!”

Like so many entrepreneurs, he dove in head first to start learning CNC. “Looking back it seems like a risky move to take, but I just knew I'd enjoy it, I knew that I wanted to become a machinist.”

Ladlee chose a PCNC 440 for its small form factor. Because his business was just getting started, he needed to fit it into the space he had available. “It fits perfectly in my single car garage, which has now been transformed into my machine shop. I was shocked (pun intended) that the 440 plugs into a standard wall outlet!”

Now that he has his machine assembled and making chips, Ladlee has churned through the TITAN Building Blocks Series and now he’s busy working on prototypes for his balisong knives.

“As soon as I completed the TITAN 10M, I began working on my own projects such as name plates, paper weights, and finally my balisong knife. I learn more every time I use my machine!”

Prototyping and Production with a PCNC 440

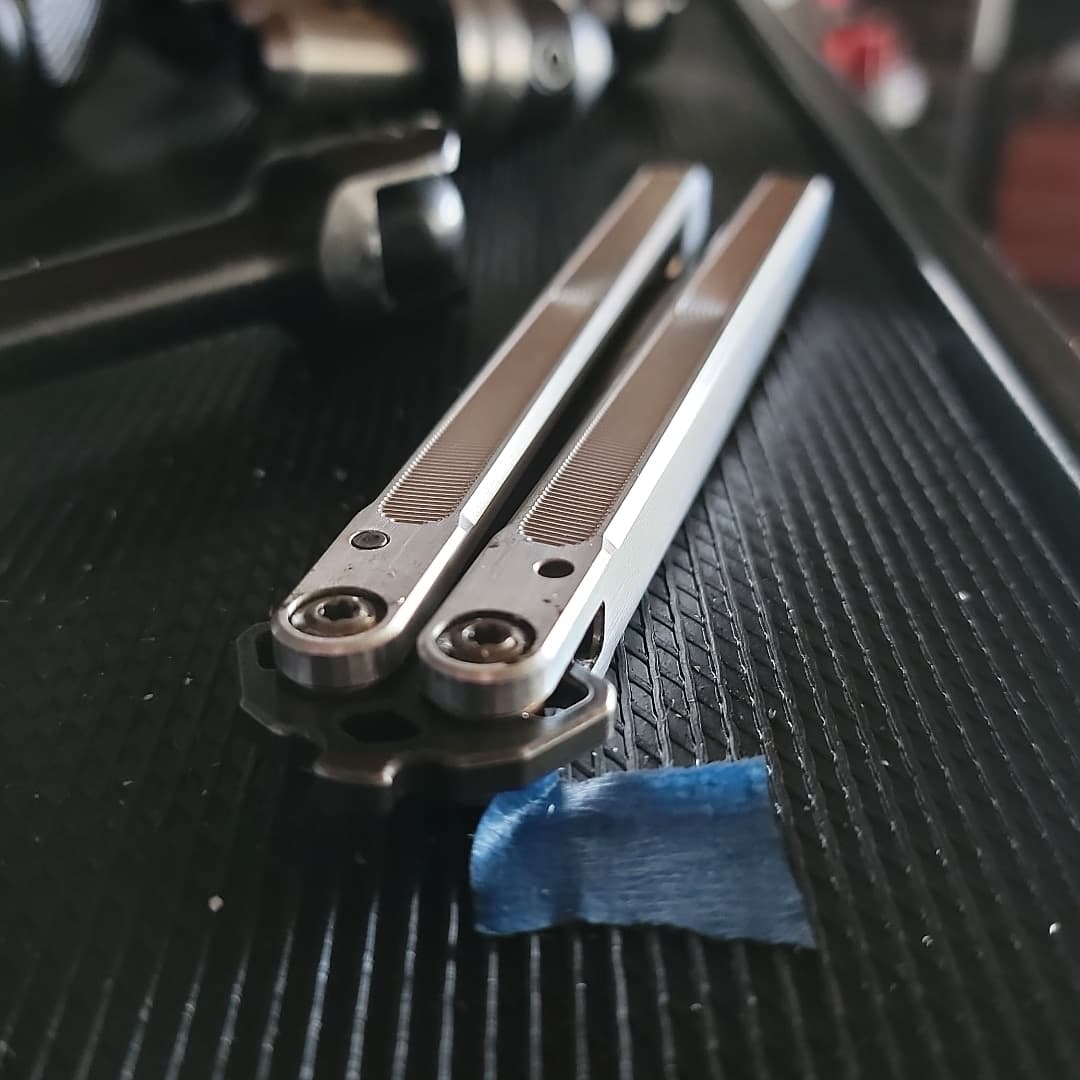

Ladlee started Patient Zero Balisong with the goal of bringing a unique custom flipper knife to the balisong community. Currently he’s using his 440 for some prototyping and product development of his knives.

“Prior to owning the 440, I was quoted for outsourced prototypes. I did the math and realized that eight prototypes would cost me the same amount as a decked out Tormach. All it did was give me more reasons to buy my machine and learn how to use it!”

He’s aiming to have a functional prototype within a year. “I wanted to give a realistic timeline to those who are waiting for this balisong to hit the market,” he explains.

While the prototype is in the works, Ladlee is still busy making chips with his machine. “It was surprisingly easy to machine handles for the first time, now I just need to focus on the small details to really perfect it. I learned a lot from the TITAN Building Blocks, and I'm using that knowledge to make my product.”

He explains that it’s the small details that are the most challenging part of making his knives. His hope is to create a product that the community appreciates and enjoys, but that requires a lot of finesse work on the product.

Once his prototyping phase is finished, Ladlee plans to also use his PCNC 440 for production as well - effectively turning his garage machine shop into a garage factory!

Check out Patient Zero Balisong on YouTube and Instagram, and watch Ladlee’s journey to becoming a knife maker unfold.

Learn more about Tormach's desktop / tabletop CNC Mill options.