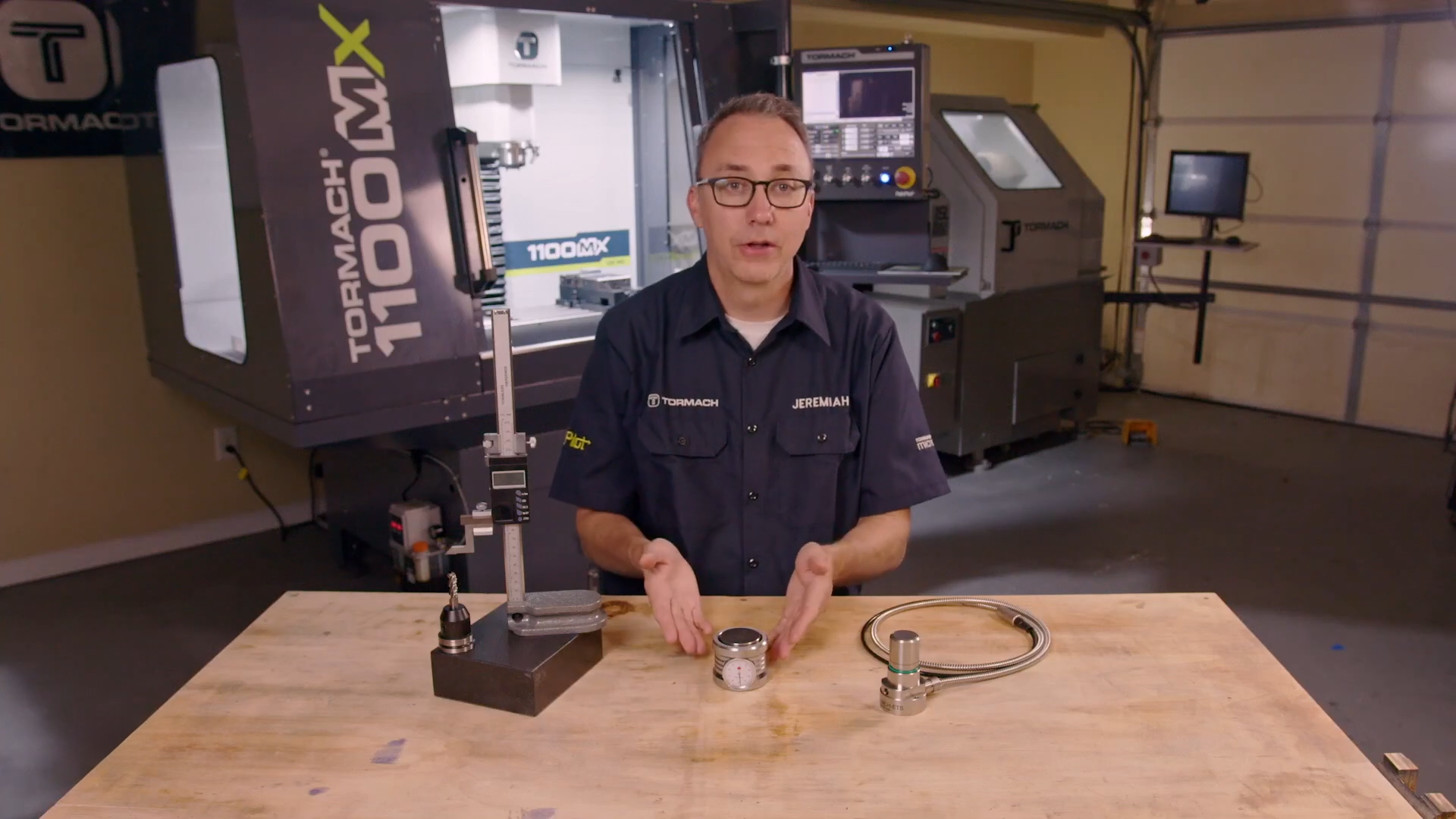

Welcome to episode five of the Tormach Garage Series. In this week’s installment, Jeremiah Daws (Maker / Machinist) will prepare our CNC beginners for an exciting milestone - running their first part. If you’re new to CNC and want to learn the basics of machining on a Tormach CNC mill, we encourage you to view the first four episodes of our series.

Previous Tormach Garage Series Videos

- Part 1: Getting Started with Your Tormach CNC Mill: A Beginner’s Guide

- Part 2: Basics Of Starting Up Your Tormach CNC Mill

- Part 3: Navigating the PathPilot® Interface on Your Tormach CNC Mill

- Part 4: Basics of Work Holding and Work Offsets in CNC Machining

Tool holder types for cnc mills

With the workpiece securely fastened in the vise, the next crucial step is equipping the machine with the right tools. This begins with two types of spindle connections , depending on which machine you have, the BT30 and the TTS (Tormach Tooling System). Each system comes with its distinct attributes, providing users with a range of tool holding options, with four common choices.

First on the list are the reliable solid tool holders. These sturdy, budget-friendly holders are designed for specific tool sizes, such as 1/4", 3/8", and 1/2", manufactured in nominal increments. These holders require a weldon flat for secure tool retention. Next up are the versatile ER tool holders, favored for finishing or light roughing operations. Ideal for end mills, drills, and even sharpies, these holders offer flexibility and prove indispensable in CNC milling. Selecting a collet slightly larger than the tool will help in optimizing clamping force and minimizing runout. Next is the drill chuck, which provides a swift and easy solution for holding drill bits. Note: the drill chuck is not designed for end mills or tools facing side loads. Lastly, we have tools that serve dual roles as both holders and tools themselves.

Tools like the face mill, shell mill, and fly cutter feature interchangeable inserts. This innovation significantly lowers operating costs, allowing users to simply replace inserts in the event of breakage. It also grants the flexibility to switch inserts based on the material being cut. When it comes to cutting tools, it is important to invest in quality tools over budget-friendly options. This minimizes potential complications during machining operations.

Different types of tools for CNC Mills

Jeremiah then dives into the differences between the various types of tools. End mills, the workhorses of CNC milling, are capable of bottom and side cutting, making them indispensable in numerous applications. Jeremiah provides insight into the diverse array of end mill sizes and shapes, from those with sharp corners to those with radius corners that prolong tool life. The ball end mill, known for its radiused end, makes it ideal for sculpting intricate 3D surfaces. There are also various options for drill bits, including the jobber bit and the favored machine length drill bit, known for its enhanced rigidity and accuracy.

Viewers will receive a crash course in threading tools, tapping, and thread mills. The intricacies of tapping are discussed, which highlights the advantages of thread mills, particularly in the event of breakage, where replacing a thread mill proves far simpler than dealing with a broken tap.

We hope this tutorial arms you with the essential knowledge about tools and tool holding in CNC milling. Get ready to bring your creative visions to life as you plan your first CNC machining project. Come back next week for another edition of the Tormach Garage Series, as we guide you towards CNC mastery, one step at a time.