In the sixth episode of the Tormach Garage Series, Jeremiah Daws (maker/machinist) dives into the crucial topic of tool cooling. There are two types of coolant options that are discussed in this week’s video: flood coolant and MQL (Minimum Quantity Lubrication).

FLOOD COOLANT

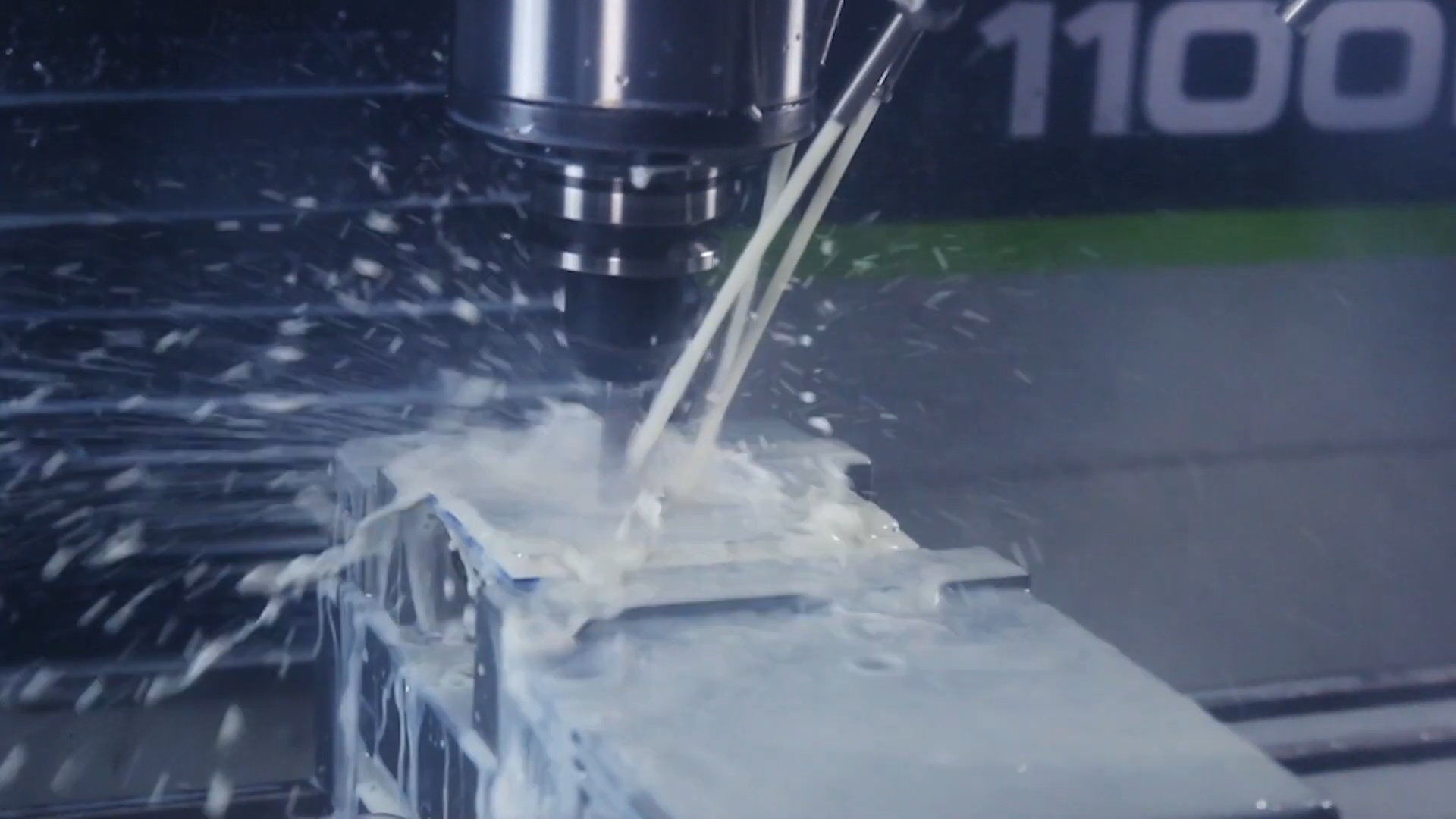

Flood coolant is great for materials prone to overheating or those that work harden (e.g. SS). This coolant is widely used due to its versatility and effectiveness in various applications. Flood coolant not only ensures proper tool lubrication but also aids in achieving optimal surface finishes. It efficiently clears chips, preventing re-cutting and ensuring a smoother machining process. However, it's worth noting that flood coolant can be messy. To mitigate this, it's advised to enclose the mill with a suitable solution, such as the Tormach enclosure or a DIY alternative.

For those opting for flood coolant, tools like a refractometer come in handy to ensure the correct coolant-to-water ratio. The QualiChem XTREME CUT 251C can be used for milling applications when mixed with water at a ratio of 4-12% (5% (20:1) is a good starting point for beginners). The 770 and 1100 series machines hold 12 gallons of coolant mix and need about 2/3 gallons of coolant for each tank refill. Additionally, an oil skimmer is recommended for machines that may sit idle for extended periods. The oil skimmer will remove skank/tramp oil from the surface of the coolant in order to elongate the life of the coolant and keep bacteria at bay.

MQL (MINIMUM QUANTITY LUBRICANT) COOLANT

Alternatively, MQL systems like the Fog Buster offer a low-maintenance option. The Fog Buster can also be better at removing chips during deeper pocketing operations. It may not be as efficient for specific tasks, such as deep drilling or with heat-sensitive materials. Fog Buster provides great visibility for light machining and as an air option during dry milling. Due to the lack of regular upkeep, this option is better for machines that will see intermittent use. QualiChem XTREME CUT 251C can also be used in a Fog Buster system when mixed with water at a ratio of 5% (20:1).

With this overview of coolant options, CNC beginners are now equipped with valuable insights for optimizing their machining processes. If you're just starting and are still a CNC novice, the Tormach Garage series has you covered. Be sure to watch the previous episodes of this highly-informative series, covering a variety of CNC basics to get you up and running.

Previous Tormach Garage Series Videos

- Part 1: Getting Started with Your Tormach CNC Mill: A Beginner’s Guide

- Part 2: Basics Of Starting Up Your Tormach CNC Mill

- Part 3: Navigating the PathPilot® Interface on Your Tormach CNC Mill

- Part 4: Basics of Work Holding and Work Offsets in CNC Machining

- Part 5: Tools and Tool Holding Essentials for CNC Beginners