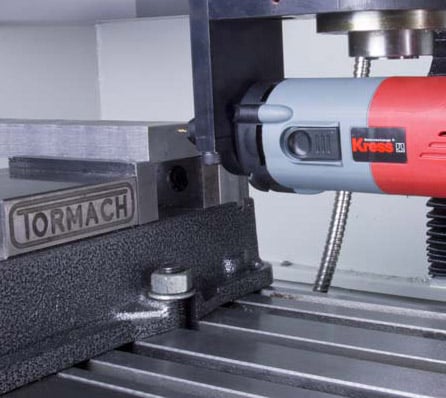

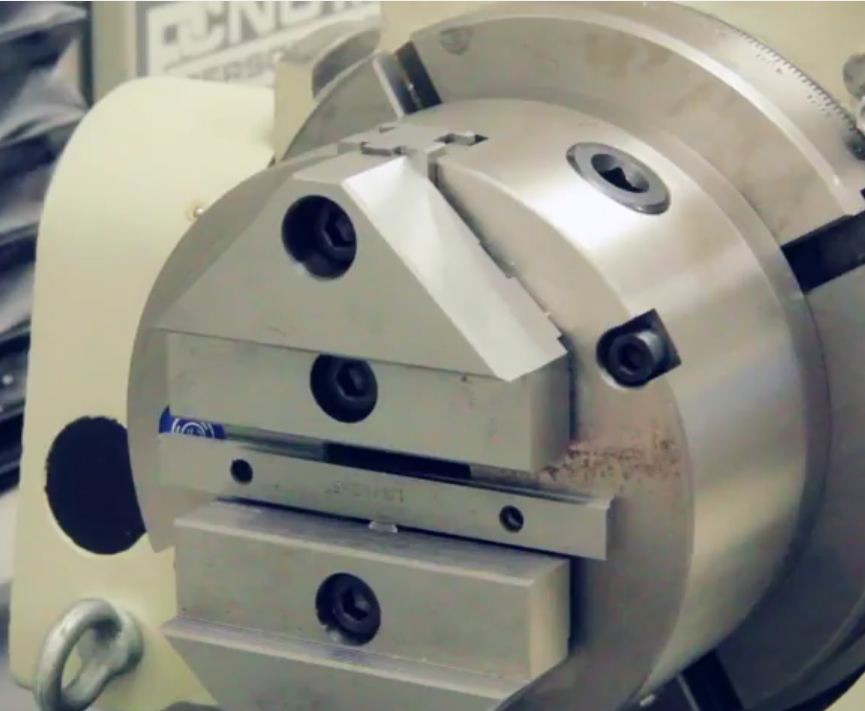

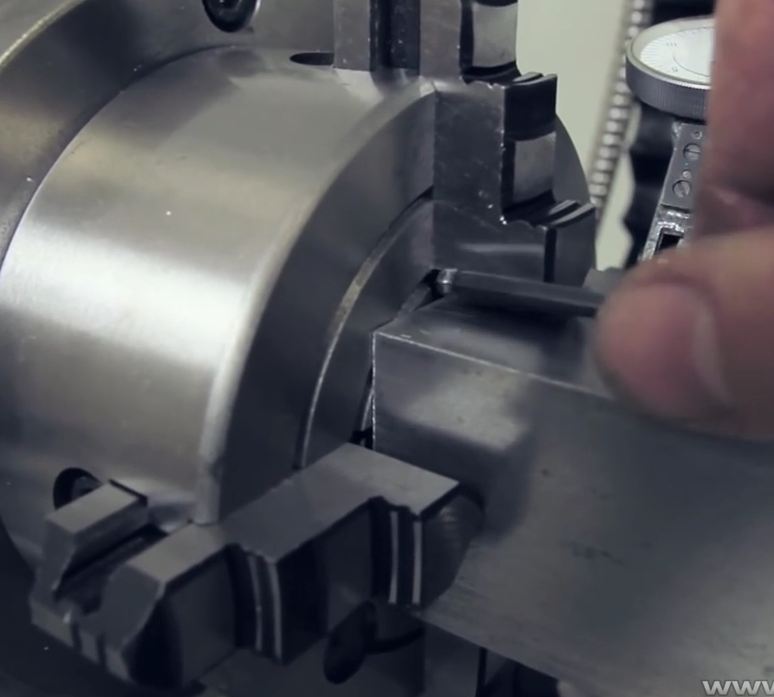

Our Speeder is a great option for doing small end mill work on a lower RPM spindle. Its a mechanical RPM increaser that takes whatever the speed of the primary machine spindle is and multiplies it 3x. On the PCNC 1100, that means that 5000 RPM becomes 15000 RPM. For the PCNC 770, you can take 10000RPM up to 30000RPM, although we rate the device for that speed for short duty cycles. Continuous operation should be limited to 20000RPM. The Speeder really excels at small pocketing and engraving applications. Here's an example of a small engraving around a bar that we did for a recent product demonstration.