CONFIGURE YOUR 770M CNC MILL

Download Technical Specifications

ENTRY PACKAGE

$9,210

Finance with 1/2 price payments for 1/2 a year!

Learn More

- ✔ 770M base mill

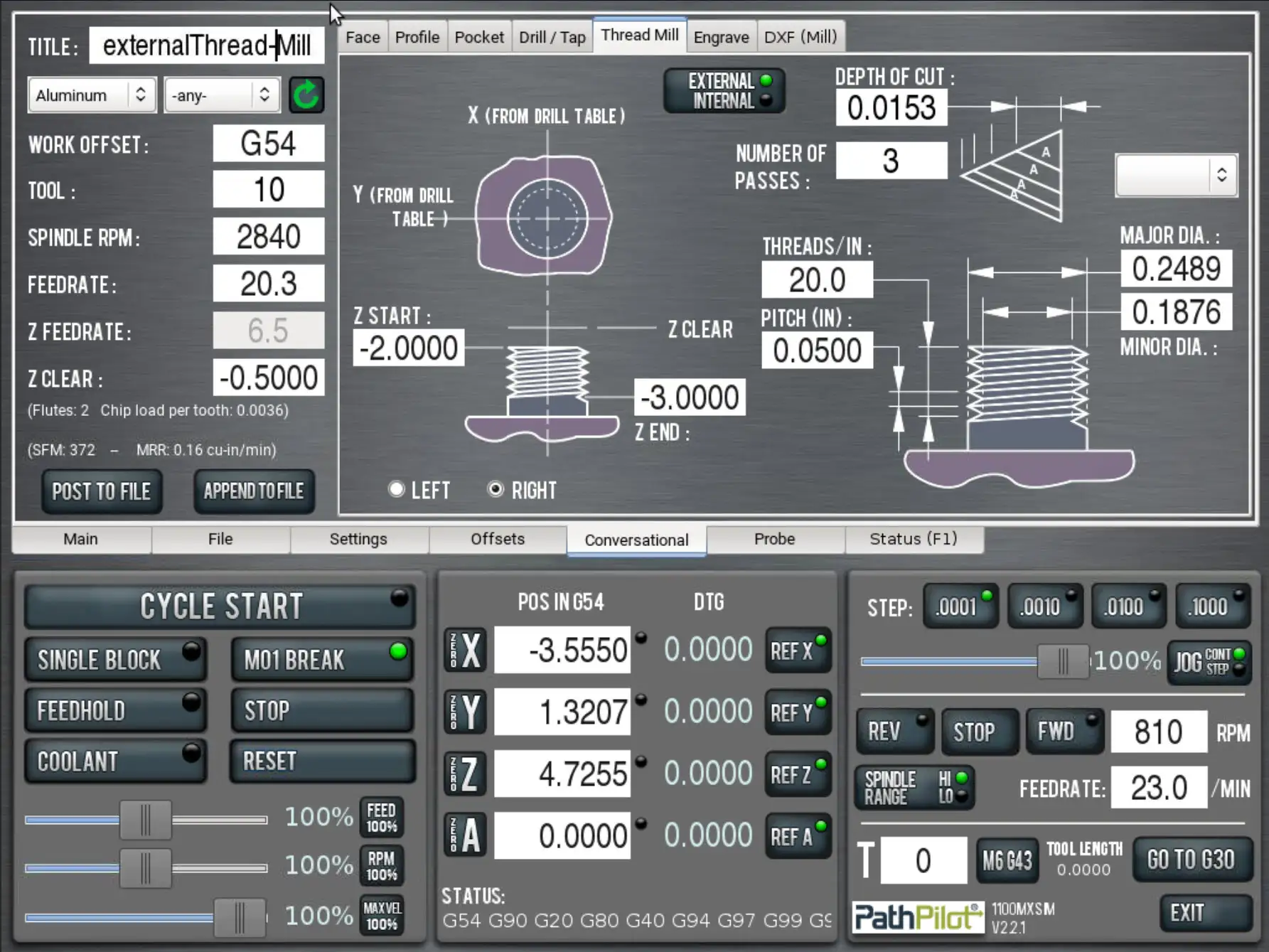

- ✔ PathPilot CNC controller

- Mill stand

- Tooling

- Vise

- LCD screen, mouse and keyboard

- Power drawbar

- 10-pocket automatic tool changer

- Fogbuster coolant kit

- Probe and electronic tool setter

STARTER PACKAGE

$14,541

Finance with 1/2 price payments for 1/2 a year!

Learn More

- ✔ 770M base mill

- ✔ PathPilot CNC controller

- ✔ Mill stand

- ✔ Toolholding set

- ✔ Vise

- ✔ LCD screen, mouse and keyboard

- Power drawbar

- 10-pocket automatic tool changer

- Fogbuster coolant kit

- Probe and electronic tool setter

STANDARD PACKAGE

$18,931

Finance with 1/2 price payments for 1/2 a year!

Learn More

- ✔ 770M base mill

- ✔ PathPilot CNC controller

- ✔ Mill stand and enclosure

- ✔ Toolholding set and tooling

- ✔ Vise and clamp kit

- ✔ LCD screen, mouse and keyboard

- ✔ Power drawbar

- 10-pocket automatic tool changer

- Fogbuster coolant kit

- Probe and electronic tool setter

PREMIUM PACKAGE

$27,146

Finance with 1/2 price payments for 1/2 a year!

Learn More

- ✔ 770M base mill

- ✔ PathPilot CNC controller

- ✔ Mill stand and enclosure

- ✔ Toolholding set and tooling

- ✔ Vise and clamp kit

- ✔ Touch screen, mouse and keyboard

- ✔ Power drawbar

- ✔ 10-pocket automatic tool changer

- ✔ Fogbuster coolant kit

- ✔ Probe and electronic tool setter

NOT SURE WHICH MACHINE IS RIGHT FOR YOU?

Schedule a Pre-Sales Consultation Download Printable Package ComparisonTHE CAPABLE 770M CUTS THROUGH A VARIETY OF MATERIALS

The 770M handles tough materials such as titanium, stainless steel and hardened steel, along with plastics and wood. Operating on single-phase power, this compact yet robust machine can be placed in tight spaces and can be easily moved when disassembled into three sub-components: column, base, and head (moving kit required). The 770M’s adaptable design supports easy upgrades as your part production needs change.

START WITH WHAT YOU NEED, UPGRADE AS YOU GROW

The 770M is a modular machine, allowing affordable entry and easy add-ons for enhanced performance. Custom accessories like our automatic tool changers (ATCs), the Tormach Tooling System, and RapidTurn CNC chucker lathe set us apart from the competition.

Why did this small business owner choose the 770M?

"Two things: size and price. Because my garage was going to be my workshop, I needed something compact. And because this was a small business, I need something budget-friendly. Tormach solved both problems. There was no way I could have fit one of the bigger machines in there, and at almost half the price of the alternative, picking the Tormach 770M was a no brainer.”

— Adam Graham, small business owner and machinist

MACHINIST LAUNCHES SMALL BUSINESS WITH 770M

EASY-TO-USE PATHPILOT CONTROL SOFTWARE

PathPilot® is the exclusive CNC controller of Tormach and is included on all machines for free. PathPilot features easy-to-use conversational software that allows you to edit programs on the fly. You can sharpen your programming skills on the PathPilot HUB, which allows you to test out PathPilot online. Learn how to program and create usable G-Code. Log in today to create your free membership.

SHOW ME MORE ABOUT PATHPILOT

Customer Stories and Projects

Interested In Learning More About the 770M CNC Mill?

Check out these great blog articles to read more...

770M INSTALLATION REQUIREMENTS

See if your space meets requirements, and see what you’ll need to do to commission your 770M.

LOOKING FOR HELP WITH YOUR 770M?

Visit the Tormach support site to find manuals, technical documents, datasheets, service bulletins, troubleshooting guides, and the knowledge base.

View Our Support Section