We empower people who make things. We get a spark when people turn their ideas into reality, their plans into parts.

Inventors and prototypers, indie manufacturers, garage-preneurs (which, if that's not a word, it sure ought to be), educators, hobbyists. These were our people, even at Tormach's founding.

Tormach's CNC Story

Like many of our users' stories, ours begins humbly in a garage....

It all began in 2001. There were no small-yet-capable CNC machines available at the turn of the millennium. Your choices for CNC mills were either Good or Small. You can only choose one. Choose Good and pay through the nose. Choose Small and sacrifice finish quality or limit the materials you can cut. There is frustration in the marketplace without a CNC machine tool that is small, affordable, and capable. That frustration is about the be the mother of innovation.

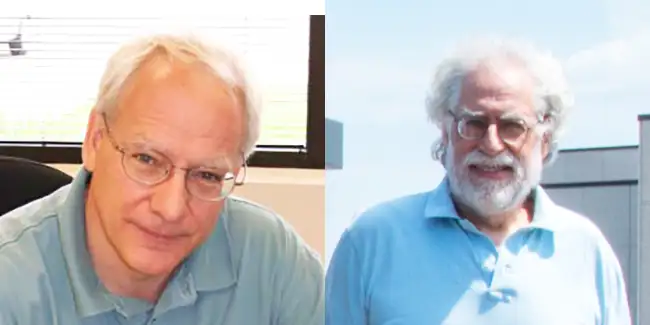

Meet Greg Jackson and Ed Korn

Greg Jackson was the general manager of a tech research company and Ed Korn owned a specialty tool company.

Both of these companies would benefit from a compact, affordable CNC mill, if only it existed. So they united to develop that mill.

This machine, they agreed, could make a huge impact for prototypers or those in specialty manufacturing. The machine they discussed wouldn't be a one-size-fits-all tool that was right for everyone, but for some, it could make a huge impact.

Greg and Ed agreed on a simple list of absolute requirements. This machine would need to be:

- CAPABLE- Personal CNC mills need to meet established tolerances. Frame rigidity is critical. As the intended audience is prototypers and specialty manufacturers, decreased spindle speed and power are acceptable, but finished part quality needs to be high.

- AFFORDABLE - Breaking barriers to enter the machining arts has given thousands of people access to making over the years. Once again, this machine wouldn't be for the whole world, but many people willingly compromise some of the machine's speed if it means they can own a machine at half the price of a competing mill.

- COMPACT -Tormach's machines would need to plug into standard electrical hookups, so you don't have to shell out money upgrading to three-phase electrical. And they would need to be designed to fit through standard doorways before assembly, so they could be used almost anywhere.

- EXPANDABLE AND MODULAR - Allowing buyers to build an a-la-carte machine gives them flexibility to buy a machine they can afford now, and upgrade it when they can. We would go on to offer performance-enhancing accessories like 4th axis rotary tables, automatic tool changers, power drawbars, and coolant kits.

- EASY TO OWN - We wouldn't stop offering value once a machine is sold. In order to make this machine truly accessible, it would need to be user-serviceable. From setting it up to performing upgrades to repairs. And when repairs are needed, it's important to offer real machinists to support users through challenges. And that support should be included in the cost of the machine. No more high cost of factory-required technicians. And controller software updates should be inexpensive or free, and simple to install. This would be a rethinking of what it's like to enable ownership.

These principles are in our DNA.

They were from day one. And these guidelines led to our founders' development of our original mill, the PCNC 1100. And these guidelines are still the core of our future.

Our principles pushed us to make improvements over the years. To make machines easier to own, we developed our own controller software, PathPilot. We built it to be user-friendly, approachable, and compatible with all major CAD/CAM software. And the PathPilot on our mills is similar to the PathPilot on our lathes, routers, and plasma tables. You learn it once, you know it. See? Easy and affordable. Because PathPilot is so central to using our machines, we launched PathPilot HUB. It's a free resource for those interested in Tormach to take PathPilot for a test drive, and it's a useful tool that allows owners to code programs when they're away from their machines. It just takes a connected web browser to use. Explore more at hub.pathpilot.com/about.

As noted before, Tormach isn't for everyone. We don't want to be a one-size-fits-all company because our users aren't one-size-fits-all customers. If our story resonates with you, it's probably because like you, we're unconventional. That's why we don't have a commissioned sales force. We want to keep our machines affordable, and paying an extra 10% to a salesperson doesn't help. We do sales consultations. It's an included service. And if our machine tools won't help you, we're okay with missing out on that sale. That's why so many in our user community are fans.

We're proud of our history. We're excited for our future. And we'd be thrilled if you put your faith in our machines to help turn your dreams into your future.