Capable, Affordable, Easy-To-Use Industrial Robot

The ZA6 is a 6kg payload industrial robot that is an easy-to-learn, capable, affordable solution for automating just about any task.

Our single-phase powered robot arm is used for welding, material handling, research, education, and can be paired with the Tormach CNC 1100MX mill for automated machine tending.

ZA6: 6KG PAYLOAD INDUSTRIAL ROBOT

Download Technical Specifications

ZA6 Robot Starter Package

Basic tools and accessories you need to get started with a robotic arm in your machine shop: base robot arm, PathPilot® controller, touchscreen monitor, keyboard and mouse, light curtain, pneumatic accessory kit, and a parallel jaw gripper kit.

Some assembly required.

Package Starting At: $19,251

Includes Preselected Build & Tooling Options

Finance with 1/2 price payments for 1/2 a year! - Learn More

IS THE ZA6 ROBOT ARM A FIT FOR YOUR BUSINESS?

Are you looking for an industrial robot arm to do welding or automated machine tending? Our expert machinists are happy to help you decide if the ZA6 robot fits your needs.

Schedule a Pre-Sales ConsultationEASY-TO-USE INDUSTRIAL ROBOT CONTROL

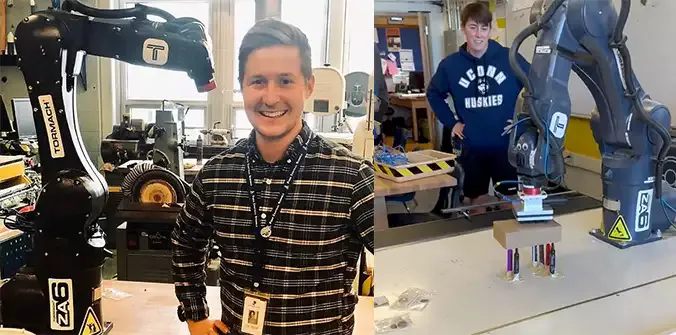

“Unbelievable! 30 minutes of class time and my students were making functional robot programs.” – Leif Sorgule, Technology & Engineering Teacher at Peru Central High School on setting up and teaching his students how to use a ZA6 robot in their class.

If you’re already comfortable using Tormach’s free and open-source control software, PathPilot®, then you can program a ZA6 industrial robot arm! PathPilot provides an easy-to-learn operator interface for all Tormach machines including robots. Plus we have a wealth of quick tip videos on all robot concepts to get you started, great tech support to help if you get stuck, and user forums for discussing more advanced topics.

Leif Sorgule, Technology & Engineering Teacher at Peru Central High School (left) and one of his students using the ZA6 industrial robot.

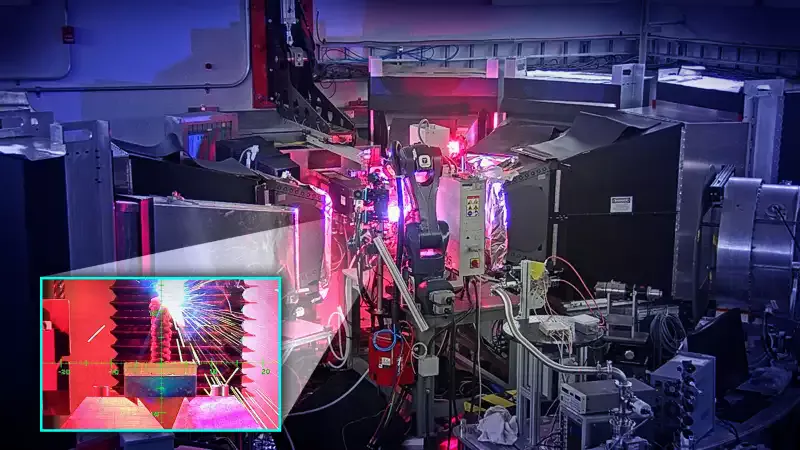

The OpeN-AM experimental platform, installed at the VULCAN instrument, features a Tormach ZA6 robotic arm that prints layers of molten metal to create complex shapes. Studying the 3D-printed welds microscopically with beams of neutrons allows researchers to better understand factors such as stress caused by heating and cooling. The experiments will help to optimize the fabrication technique for more mainstream use. (Credit: ORNL/Jill Hemman)

ROBOTICS RESEARCH APPLICATIONS

Tormach’s PathPilot® robot control system is built on ROS. All system variables are exposed to the user via the API, many in real-time (1 kHz), offering tremendous advantages to people already familiar with ROS programming. And because Tormach is committed to open-source, code is public on GitHub for review, use, or modification. The open-access nature of the ZA6 creates real opportunities for robotics research.

Read our whitepaper to learn how customers like Oak Ridge Laboratories and Georgia Tech are using the ZA6 in their research.

Download WhitepaperAUTOMATED MACHINE TENDING

The ZA6 industrial robot arm is used in a variety of applications, but our primary intent with the robot has always been to tend Tormach CNC machines. The robot seamlessly connects with Tormach machine tools and we’re committed to making machine tending as easy as possible. See how the Tormach team leveraged the ZA6 robot with the 1100MX CNC mill, resulting in surprising success with minimal effort.

Watch the recording of our recent machine tending webinar to learn more.

What made a ROSCon attendee stand up and thank Tormach?

"Not a question, just want to congratulate you for bringing together those two open-source islands of Linux CNC and ROS. There have been many attempts over the decades. Thanks for making it happen, finally."

REAL TIME MOTION CONTROL IN ROS UNITING HAL WITH TORMACH’S ZA6 ROBOTZA6 ROBOT ARM VIDEOS

LOOKING FOR HELP WITH YOUR ZA6 Robot?

Visit the Tormach Support Site to find Manuals, Technical Documents, Datasheets, Service Bulletins, The Knowledge Base, Forums and Troubleshooting Guides.

View Our Support Section